oil

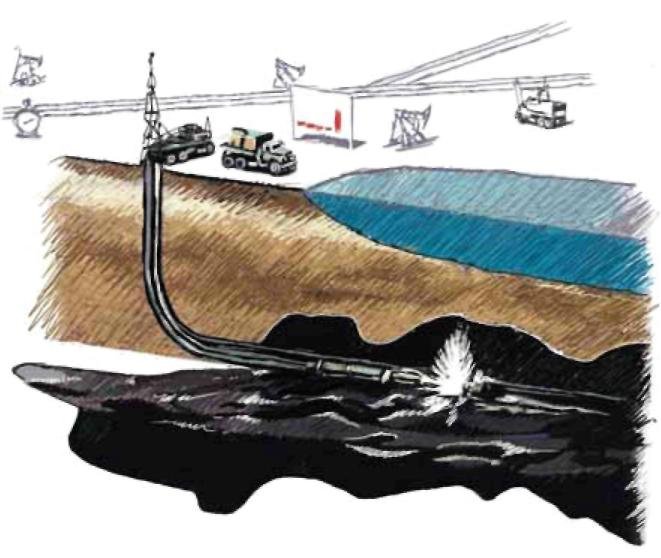

When the well is already producing oil, the flow from it is weakening over time. And he is weakened for various reasons, including because of the so-called colmatation. This is a complex process in which, to a greater or lesser extent, various phenomena occur: the formation of a clayey crust on the walls of the well, the swelling of clayey rock particles, the precipitation of chemical compounds, and the penetration of solid particles into the formation. How in this case to clear the pores? Workers in the well can not be lowered, the hole is too narrow, and the injection of chemical reagents does not always help well and can harm the environment. In addition, cleaning the well, it would be desirable not to destroy the well itself. And in Russia to all of the above, you need to add severe climatic conditions for the work of staff …

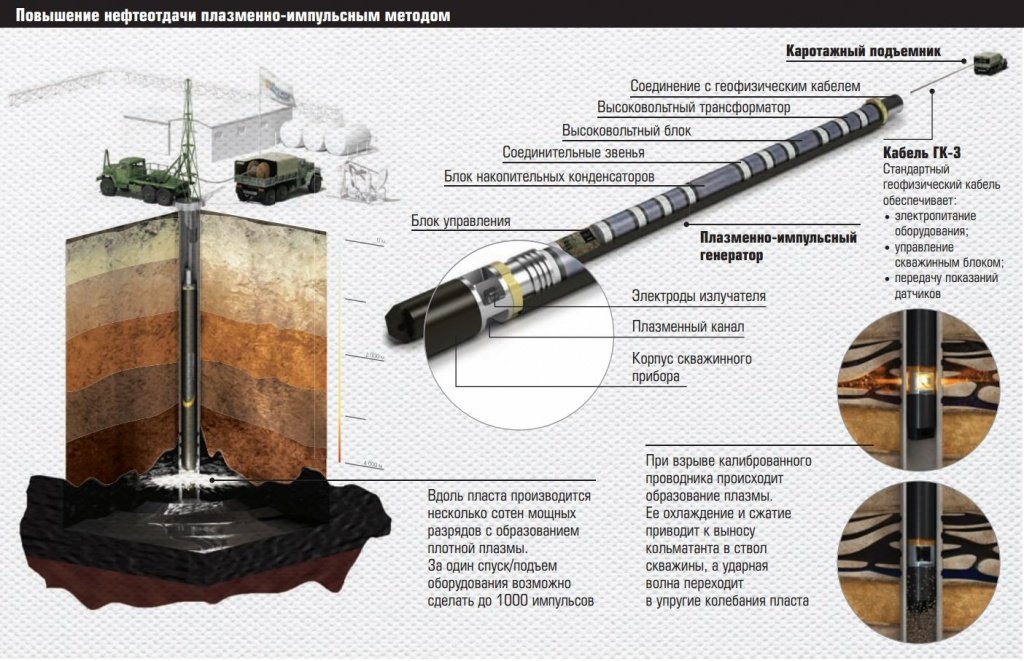

But in the mid-90s, the original method of cleaning wells was invented – it is a plasma-pulse effect on the formation. Its essence lies in a submarine spark discharge, in which shock waves arise, large liquid displacements, infra- and ultrasonic radiation, powerful electromagnetic fields (tens of thousands of oersteds), as well as multiple ionization of compounds and elements contained in a liquid, and the formation of a low-temperature plasma with a temperature Up to 4000 ° C. At the same time, the pressure reaches 1000 MPa.

Source: www.novas-energy.ru

How is such a discharge created and why such cosmic conditions do not destroy the well?

The process of plasma-pulse action is as follows: a cylindrical generator is lowered into the well, In the spark gap of which there is a metallic conductor. After this, a large current is passed through the conductor so that the conductor instantly evaporates and turns into plasma. Since discharge occurs in water, a chemical reaction of the metallic vapor with water takes place during the explosion, and the current passes through the products of this reaction, which also explode. As a result, a gas bubble forms. In these cases, a compression wave propagating in a liquid turns into a shock wave.

The expansion of the bubble occurs until the kinetic energy of the spreading stream is completely transferred to the potential energy of the bubble, the pressure in which is less than the hydrostatic pressure. Then, under the action of hydrostatic pressure, the fluid moves backward, the potential energy again turns into the kinetic energy of the converging flow. When the cavity is slammed, the gas pressure in it increases sharply. Under the influence of this pressure, the liquid is thrown back and the process is repeated in the form of subsequent damped pulsations. Almost all of the energy in this case spreads horizontally, alternately compressing and stretching the medium, as a result of which the colmatant is carried to the wellbore. Such horizontal impulses do not violate the integrity of the well, but at the same time spread over long distances and can even increase production in neighboring wells.

Source: www.novas-energy.ru

The device is a cylindrical body in which a high-frequency generator is sequentially located (creates a sequence of pulses), a high-voltage unit (creates a high voltage), a storage capacitor bank, a device control unit, emitter electrodes And between them a plasma channel, as well as a device for supplying electrodes to the plasma channel. To create a discharge, capacitors with a capacitance of about 50 – 200 μF, charged to 3,000 – 6,000 volts, are used. Since it is impossible to transfer more than 1,000 volts to the special cable (it still withstands high mechanical tensile loads), the capacitors and the voltage-boosting transformer are located in the device itself, which requires the developers of devices to be extravagantly inventive.

It should be noted that the method was invented in Russia at the Mining University (St. Petersburg). So we are proud of the Russian engineers!