inkjet

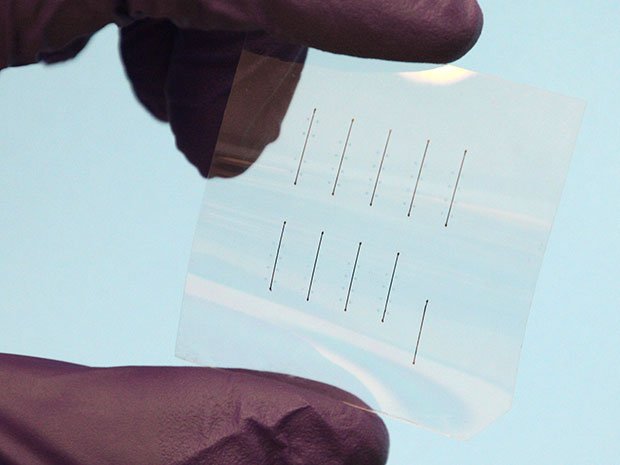

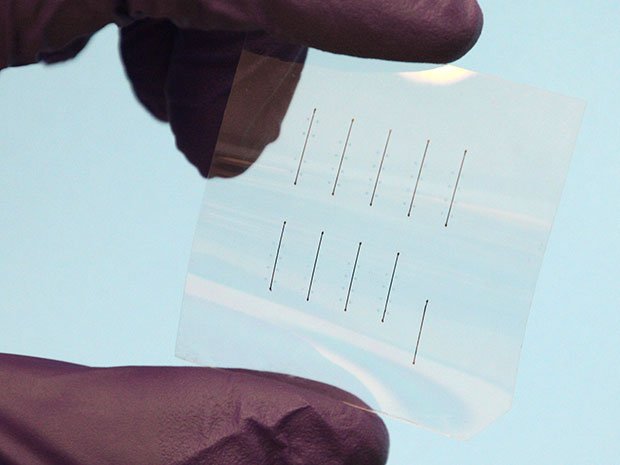

Fast three-bit memory cells printed on a standard inkjet printer

Up to now, two types of memory have been used in computer devices : 1) energy-independent, but relatively slow flash memory; 2) volatile, fast RAM like DRAM. But an ideal memory combines the advantages of both these types – it must be fast for writing and reading, but at the same time it is non-volatile and not destroyed, including from multiple read operations. Inkjet Printer. This type of memory is now being developed by research teams from different companies. One of the proposed types of memory is Conductive Bridge RAM (CBRAM), a kind of Resistive RAM (ReRAM).

CBRAM really combines the properties of RAM and flash memory. It has a simple conductor-dielectric-conductor structure. The resistance of the CBRAM cell is changed electrochemically between the two states. If an appropriate voltage is applied, the metal thread forms an interconnection between the two electrodes, which corresponds to a low resistance in the ON state. The filament can be partially dissolved at another voltage, returning the cell to the high resistance state (OFF).

One of the most promising directions in the development of ReRAM is the printing of memory cells on an inkjet printer. This process does not require the use of lithography and clean room, significantly reducing the cost of production of electronics. In addition, using a substrate of cheap film, we get memory, which is great for flexible electronics.

Previous research in the field of printout of memory on a printer focused mainly on electrohydrodynamic methods of printing. Unfortunately, at the moment all memory devices printed with standard jet memory technology require additional production stages, such as electroplating or lithographic structuring.

But now physicists from the University of Applied Sciences of Munich have found the CBRAM inkjet printing method that does not Requires additional post-processing. From the printer come fully ready to use devices resistive RAM. The method is easily adapted for roll technology – the process of manufacturing electronic devices on flexible plastic rolls.

A key element of ReRAM is an insulating layer that represents space for the migration of ions and the creation of metallic filaments. Many materials have tried in this role, including Ag 2 S, ZnO, SiO 2 GeSe and polymers, with SiO 2 showing the best switching characteristics Among all.

German physicists used the Honeywell Accuglass 111. material for the insulating layer. This is a methylsiloxane polymer that contains the layer of the above-mentioned SiO 2 . This polymer is then applied a few additional layers on the inkjet printer. The researchers used a standard commercially available inkjet printer FujiFilm Dimatix Materials Printer DMP-2850, which is used for printing different materials. In this case, three liquid materials are needed:

- an electrically conductive layer of silver nanoparticles;

- spin glass (dielectric);

- Electroconductive organic polymer PEDOT: PSS.

As a result, really flexible plates with rewritable RAM are obtained. According to the authors of the scientific work, the re-recording of information into such devices by electrochemical means requires a relatively small current: 1 microamperine for recording, 0.5 volts for switching to ON (metal conductor formation) and negative voltage -0.05 volts for switching to OFF .

Current strength (in nano amperes) and recording voltage, as well as the corresponding resistance and voltage characteristics

Electrical Voltage for transition to the ON state with respect to the sintering temperature of the spin glass

Most importantly, the researchers achieved a switching speed from ON to OFF and back to 300 nanoseconds. Hence, the memory can work at a frequency of 3.33 MHz. It’s really fast memory.

It’s interesting that memory cells produced in this way are potentially multi-bit. That is, varying the voltage, you can set a different resistance in each cell of memory and thus record in them not only 0 and 1, but also other values. Researchers say that each cell is capable of taking eight distinct electronic states (000, 001, 010, 011, 100, 101, 110 and 111, that is, three bits). It’s not quite clear how to use 3-bit memory. Maybe just to improve the storage density of information.

Now the density of the memory on the plate depends only on the resolution with which the printer is capable of printing. Model DMP-2850 prints 100 × 100 micron cells, but any improvements in inkjet technology will instantly lead to an increase in memory capacity.

One memory cell under a microscope

]

Scientists hope that the printing of flexible electronics will become as revolutionary technology as 3D printing from plastic. Any person will be able to print a new electronic card for their home appliance or simply pre-print the RAM for a personal computer if necessary.

The printed memory successfully passed 10,000 reads per 0.1 V.

Scientific The work was published in the journal Applied Physics Letters in April 2017 (doi: 10.1063 / 1.4978664).

Hello. I have checked your myviral-box.kreadevs.com and i see you’ve got some duplicate content so probably it is the reason that you don’t rank hi in google.

But you can fix this issue fast.

Thank you for the comment